Sewing machines are of great value for all sewists, and it’s essential to ensure they work correctly and that all components are in sync. If not, they will not produce the results that you are looking for.

Due to the number of components in a sewing machine, it can be challenging to manage, so many people struggle when they have one in front of them.

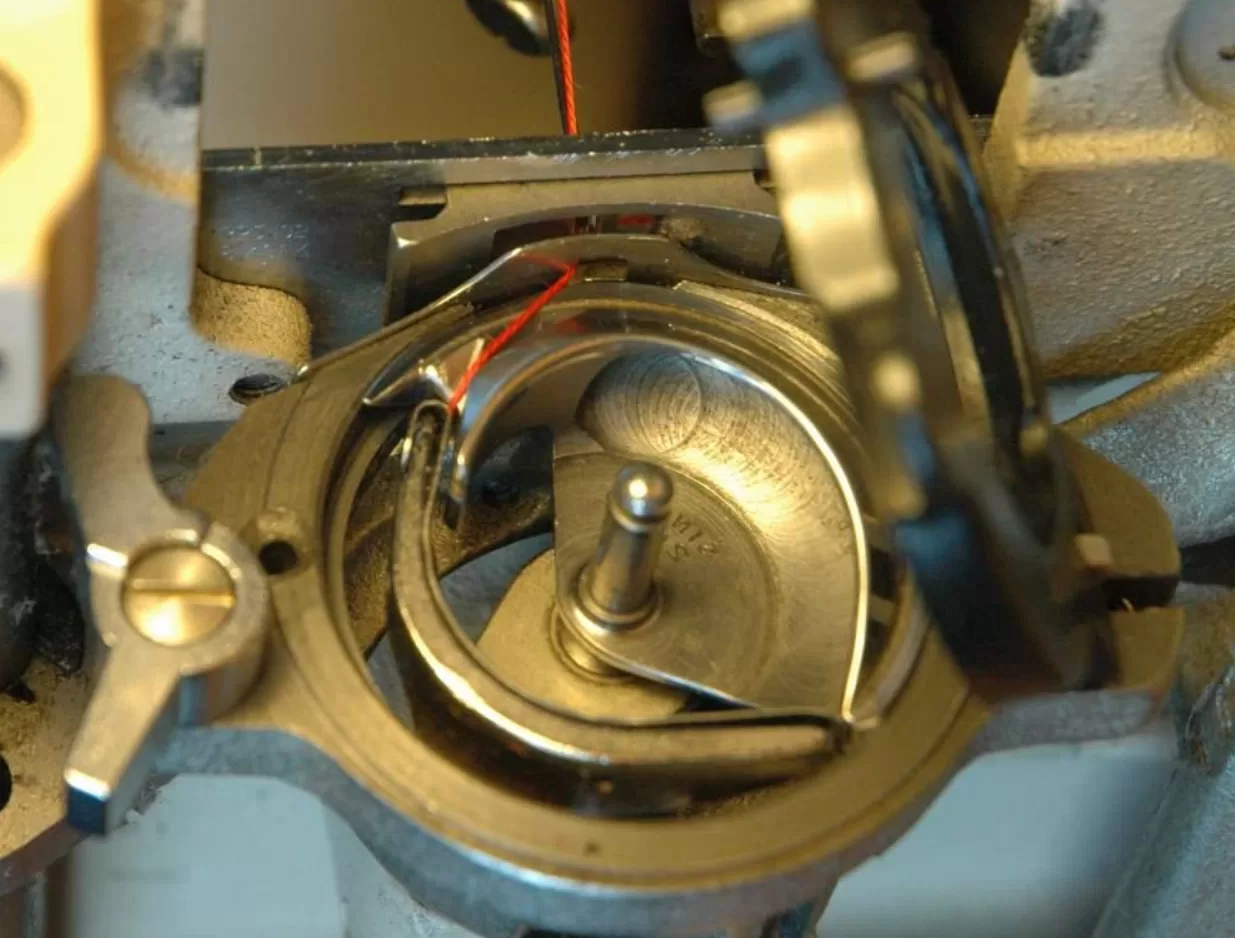

A component that is tough to manage is the shuttle. This guide will look at what the shuttle in a sewing machine is all about and some of the problems that come along with it.

Everything you need to know about problems with a shuttle

That is a component in the sewing machine that is usually made of plastic or metal. It is small and flat. It is designed to work with the thread cutter to ensure things are cut evenly and in line with what is required. That is the part that ensures the stitches don’t stick during the sewing process.

The shuttle is critical when transferring the fabric to the needle. If things are not working, the stitching will be off and not turn out as required. Sometimes, the sewing machine will shut off independently due to this issue.

The two issues that popped up included binding and skipped stitches. Skipped stitches refer to problems with how much fabric there is.

When there is not enough fabric, it starts to get ridged. Binding happens when the shuttle is tangled, and that causes the fabric not to go through as needed.

Some issues can arise regarding a sewing machine and its shuttle, and you must address these problems to get the sewing machine to work the right way.

⊳ Timing Issue

It starts with the timing being off. When the shuttle is not getting the top thread right, it will not be as useful as needed.

You have to take the time to work on the timing issue and ensure it is in line with what is required to get the sewing machine to work properly. You will have to think about what’s needed to ensure the machine is as efficient as it needs.

If you take the time to fix this problem, it will work out properly.

⊳ Dirty Shuttle

The shuttle may need to be cleaned, which is the underlying problem. The shuttle is not going to manage the thread the right way when this occurs.

You should take the time to diagnose the issue and then figure out what’s wrong with the machine.

⊳ Misaligned Shuttle

There can be issues with how the shuttle is set up, which makes the thread out of line. You have to look into how the shuttle is set up and if it has recently been cleaned, as that can lead it to stop working the right way.

It is also possible for issues to arise regarding how the shuttle works with the top thread.

⊳ Needle Issues

There may be problems with how the needle works. That will only sometimes come down to the shuttle, but ensuring things work as needed is still essential.

The shuttle will not correctly work when there is a problem with the needle, and it must always be straight and sharp. That is how you want to prevent issues with how the shuttle works once used.

⊳ Binding Issues

Binding is a problem with shuttles occasionally, which means the fabric begins to bind with the shuttle wheel.

To test this, you can put a piece of fabric with the wheel and then move the shuttle. If the material is moving, it will be fine. If not, the binding will require fixing to get the sewing machine back on track as soon as possible.

⊳ Thread Bunches Up

Thread bunching is a real concern when sewing and is hard to deal with. You have to address this to ensure the thread is in good condition.

When the shuttle is unstable, you will not enjoy how things turn out. That can be due to dust or something being off with the thread.

When this happens, the shuttle will not work the right way. It’s essential to clean the sewing machine and look at the needle plate, including what’s happening underneath it, and that is a must to keep things as clean as possible.

That becomes a legitimate issue for those dealing with a too short shuttle. The same goes for the bobbin post being the wrong height, which can cause the thread to get trapped and not get to where it needs to go.

A malfunctioning shuttle fix tips

It is possible the shuttle will not move correctly, which will lead to trouble over time. You might not be able to get the sewing machine to work the right way, or it will not work at the speed you want it to. Look into this to ensure the fabric is in good health, and things don’t break down to the point that it does not work.

▸ Keep tabs on the tension

The tension must be good with the shuttle, which will let the fabric move as required. If it is not enough, the shuttle will stop working correctly. The same goes for the too-high tension, as that is how it will get stuck.

You can work on adjusting the tension by testing the screws. That will let you move the shuttle around to see if it gets stuck. The same goes for pulling the thread to ensure it’s taut. That is the best way to make sure it stitches as needed. You don’t want the stitching to come undone, which can happen if you are not careful about the tension.

▸ Look at the seam allowances

It is essential for there to be space for the seaming, which is critical, or it will start to bunch up, which is not ideal.

You will also want to take the time to clean the machine and ensure it is as robust as it needs. That includes how the dirt and debris are managed over time. You don’t want a situation where the machine is unclean.

Frequently asked questions

Can a machine shuttle hook be replaced at home?

Yes, changing the sewing machine shuttle hook at home is easy. Take off the two screws, hold the hook, and remove it from the machine. You will then want to swap out the sewing machine shuttle hook with something the same size to ensure your machine works as needed. The manufacturer will often have the right part.

What will happen if the shuttle does not work the right way?

If the shuttle is not working the right way, it will not sew correctly, which means you will not get the right seam.

How can you know when the machine has a shuttle?

It will come down to the sewing machine you’re working with. There are two types of shuttles, one on the oscillating shuttle hook or the rotary hook. You can figure this out by removing the bobbin and seeing how the shuttle moves as the balance wheel turns.

What’s the purpose of the shuttle in the machine?

The shuttle is designed to work on the thread and move it to the needle.

What is the weaver’s shuttle?

This part of the sewing machine will take up the thread. It is the bobbing winder and will do well as it begins winding bobbins as you sew.

It is possible for the weavers also to hold the stitch tight. That includes using needle guides to ensure the needles don’t bend.

What’s a shuttle run?

A shuttle run is a part where the shuttle is kept in place as the machine runs.

Final Thoughts

If you want to address this problem, it’s time to get rid of the stitching and thoroughly assess the shuttle. If it is damaged, you must swap it out as soon as possible to ensure the shuttle does not continue to falter. You will also want to think about cleaning it.

A sewing machine that does not work properly will lead to major issues, impacting the stitching and the fabric. Always contact a specialist when the stitching is off; they can help.