Using a sharp needle when working on your fabric is always recommended to ensure the sewing work progresses consistently and quickly. A dull needle damages the material you are working on and your sewing machine’s motor.

You can tell the needle on your sewing machine is dull when it starts to make a popping or thud sound, and the blunt needle struggles to make a hole through the fabric. Alternatively, switch off the sewing machine and use your finger to gently press against the needle to feel and confirm whether it is sharp or dull.

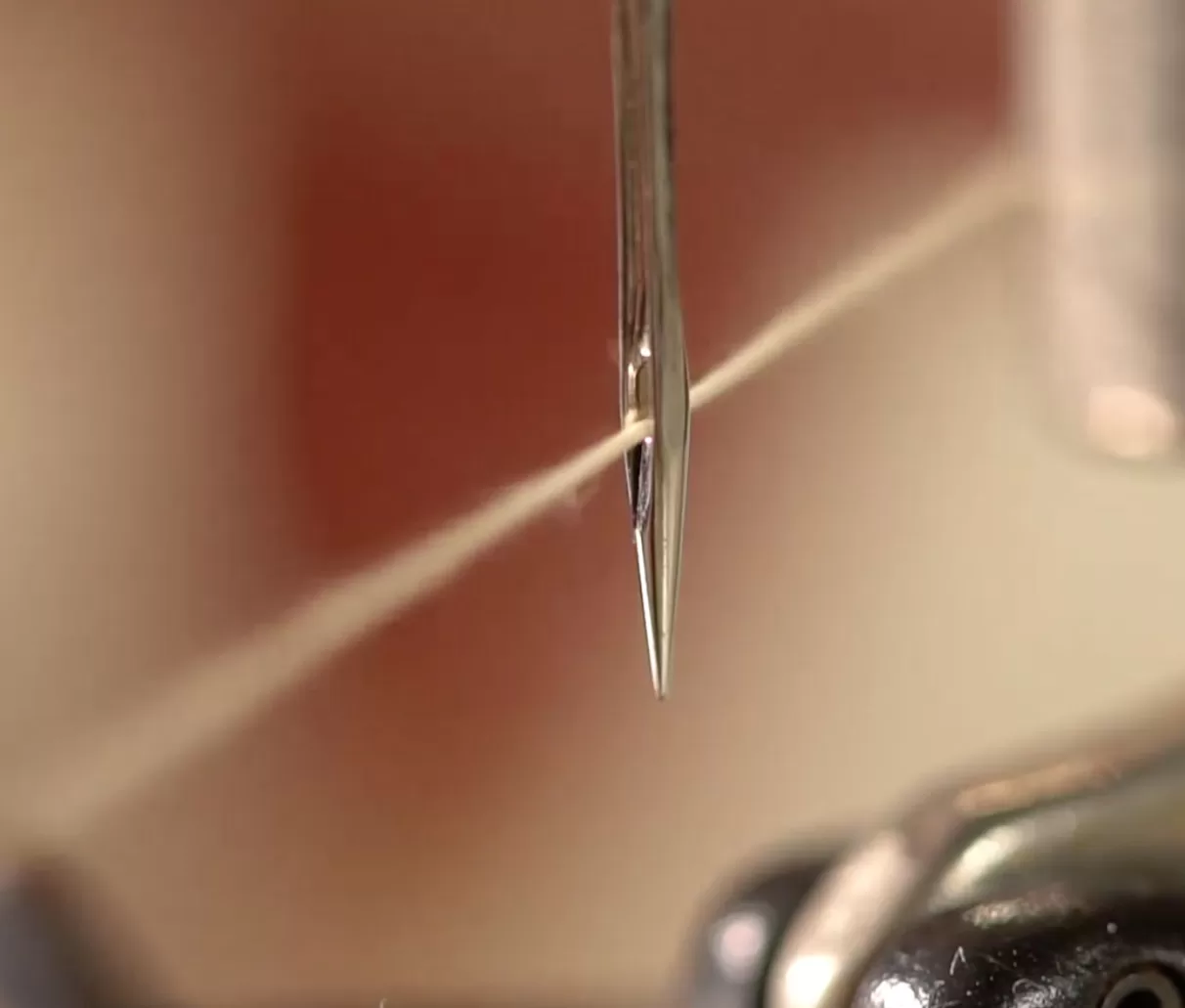

Also, you can use a magnifying glass to check how sharp or dull the needle point is—this is an excellent way to know if it is time to change the needle. Here are other top reasons your sewing machine needle has become dull:

● It gets louder than expected

When the sewing machine’s needle becomes dull, you will hear the machine become more audible than normal. Also, you may begin to listen to the needle make a “thunk” noise every time it pokes the fabric. It is easier to notice this sound when the sewing machine is moving at a slower speed.

● It skips some stitches

A dull needle usually destabilizes the sewing machine’s timing enough to cause it to miss some. Other reasons can cause this problem besides a blunt needle, but the condition of the needlepoint is the right place to start.

● It starts pulling threads on the fabric

A ruined or dull sewing machine needle will likely catch the fabric fibers as it pierces through and may remove threads and wrinkles near the seamline. You may have to sharpen and polish the needle to eliminate this issue.

● The needle’s point feels rough

You may detach the needle from the sewing machine and confirm if it has irregular or dull edges. Gently run your fingernail on the side of the sewing machine needle or rub the needle gently on your skin to know how sharp or dull it feels. You might catch your nail on the needle’s surface if the needle has become dull or damaged.

● Look for apparent flaws

With a magnifying glass, you can check the needle to see if you notice any apparent dullness or signs of abrasion.

● When you’ve been using it for a long time

Usually, a sewing machine needle starts to become dull after about eight hours of consistent use. If you are still determining how effective the needle is, consider changing it after every project. Or, in general, you can replace the needle after three thread bobbins have been fully used.

When is the right time to replace hand sewing needles?

It is best to replace your hand-sewing needle as soon as you spot any signs of damage. Ordinarily, this happens when you have constantly been sewing for about ten hours. In addition, the type of fabric you are working on and the sewing style you are using can cause the needle to lose its efficiency faster.

The sharpness of a hand-sewing needle lasts for between one and two months. Nonetheless, consider replacing the needle when the quality of work is compromised because the needle has become dull.

The needle is one of the most affordable parts of a typical sewing machine. For this reason, it is economical to change the needle as you move from one stitching project to another.

As a rule of thumb, a sewing machine needle can last between eight and ten hours of constant sewing work or about three full bobbins of thread.

Professional sewists can use most sewing machine needles for between six and eight hours. However, working on tough fabric that is challenging to pierce through will significantly reduce the useful life of your sewing machine needle.

How to maintain the sharpness of your hand needles?

Sharpening your needles with an emery board as they wear out is the best way to keep hand needles sharp. As long as you use them, it is impossible to stop needles from becoming dull. However, if you have a few special needles that you would like to retain forever, consider sharpening them whenever they show any dullness.

Have you seen the tiny strawberry that has pincushions?

Unbeknownst to many, the function of the strawberry is similar to that of an emery strawberry—to sharpen your needles. For this reason, if you do not have an emery board, you may rely on this tool.

The emery strawberry contains a substance referred to as emery. Remember that the emery board placed on the nail clippers you use for nail foiling refers precisely to the same thing.

Emery is produced from aluminum oxide (corundum) and iron oxides like magnetite or hematite, which are also helpful for needle polishing. You will also need to identify the emery powder grade based on the level of sanding and polishing you are looking for.

What is the best way to clean old sewing needles?

You can easily clean your needle by washing it with water to get rid of the dirt and sweat it has gathered from your hands. After working with your needle for some time, it may appear dirty. On the bright side, you might find the needle more straightforward and efficient after cleaning it.

Can you sharpen a sewing machine’s needle?

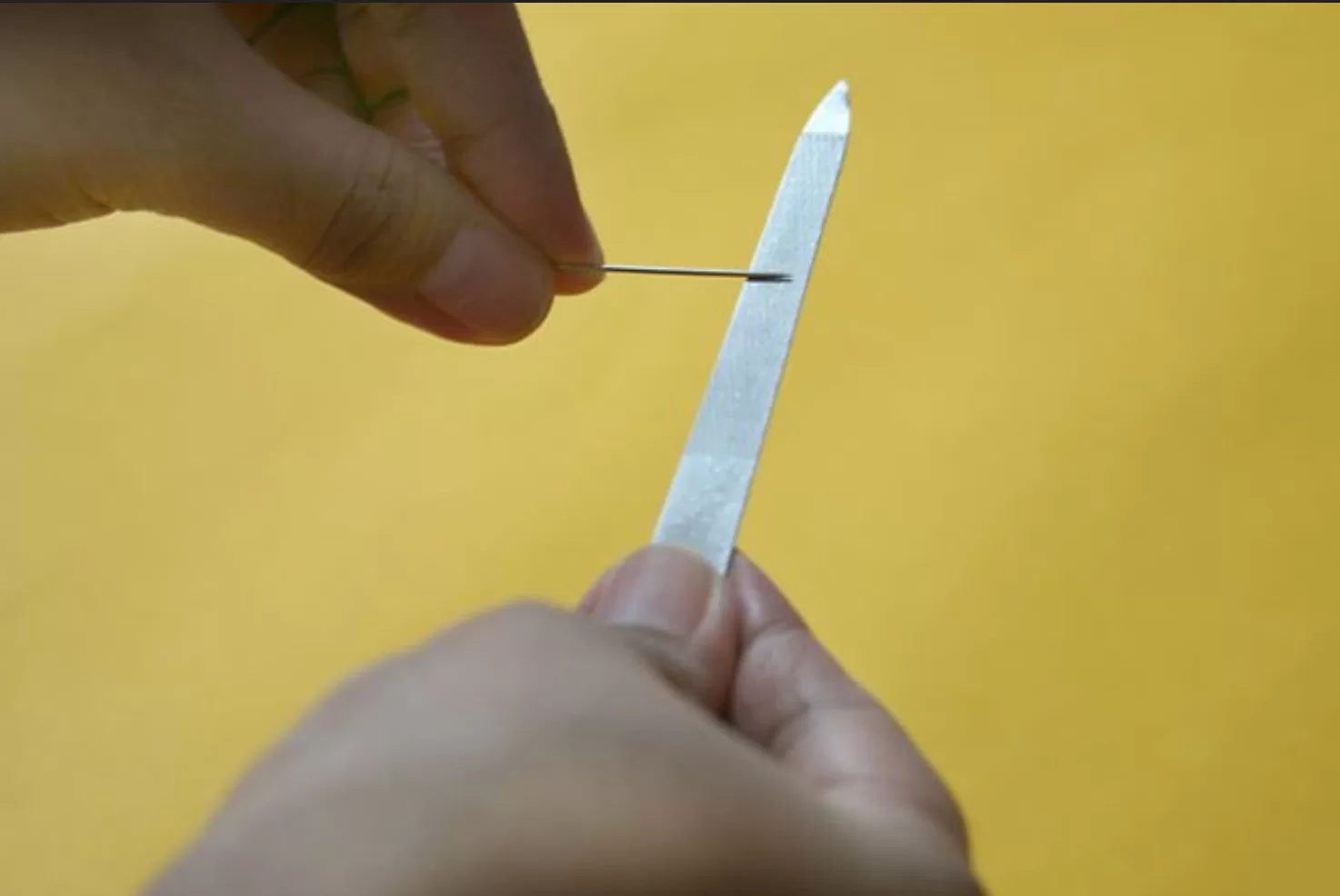

If you cannot immediately replace the damaged or dull needle with a new one, you may sharpen it. To sharpen the needle, use an emery board with a grit number between 800 and 1500. Alternatively, use any other sharpening tool with an equal level of grit.

When using an emery board, you will only need to run the needle over the board’s gritty surface several times and afterward use your finger to feel its sharpness. You may need to repeat this step several times until the needle regains its sharpness. After sharpening the needle, you will need to polish it.

Polishing a needle requires you to have a metal-polishing paste or use some toothpaste. While polishing the needle, you will see it becoming darker, indicating that the polishing is working correctly.

Another way is to use bar soap to enhance the needle’s efficiency. Stick it inside the bar soap before you start sewing with it. The soap smooths the needle, enabling it to go through the material quickly. Consider repeatedly sticking the needle in the bar soap at intervals to maintain its functionality.

Where to take your old sewing needles?

Consider donating your old sewing needles to someone who needs them or disposing of them appropriately. You should donate your needles if they are still in good condition and you are only changing them to attain greater efficiency and quality of work. Use a compact box to store your old needles and donate them once the box is full.

If your needles are no longer functional and cannot be salvaged, find an empty container or spice tin to store them in. Avoid dumping the needles directly in the dustbin together with other forms of garbage. That is to prevent the needles from piercing the garbage bag and falling out, which can be risky for humans and animals.

When the tin is full, you can take it to a local pharmacy to help you get rid of the needles correctly.

What to look for if you need a new sewing needle?

When looking to replace the needle, choose the ideal needle that suits the stitching style and fabric you are working on. With the correct needle, your stitching work will flow smoothly.

Final thoughts

Sewing with a dull needle is tedious, as it forces you to do twice the work you would with a sharper option and potentially exposes your fabric to damage. It would be best if you focused on improving the sharpness of your sewing machine’s needle by sharpen it or simply buying a new one.

Importantly, using the correct needle is the most recommended hack to safeguard the condition of your sewing machine and extend its longevity. With the ideal needle, the machine is not forced to overwork and goes through the fabric effortlessly. This way, you can avoid having to repair the sewing machine now and then.